Variable Frequency Drive (VFD) for AC Motors

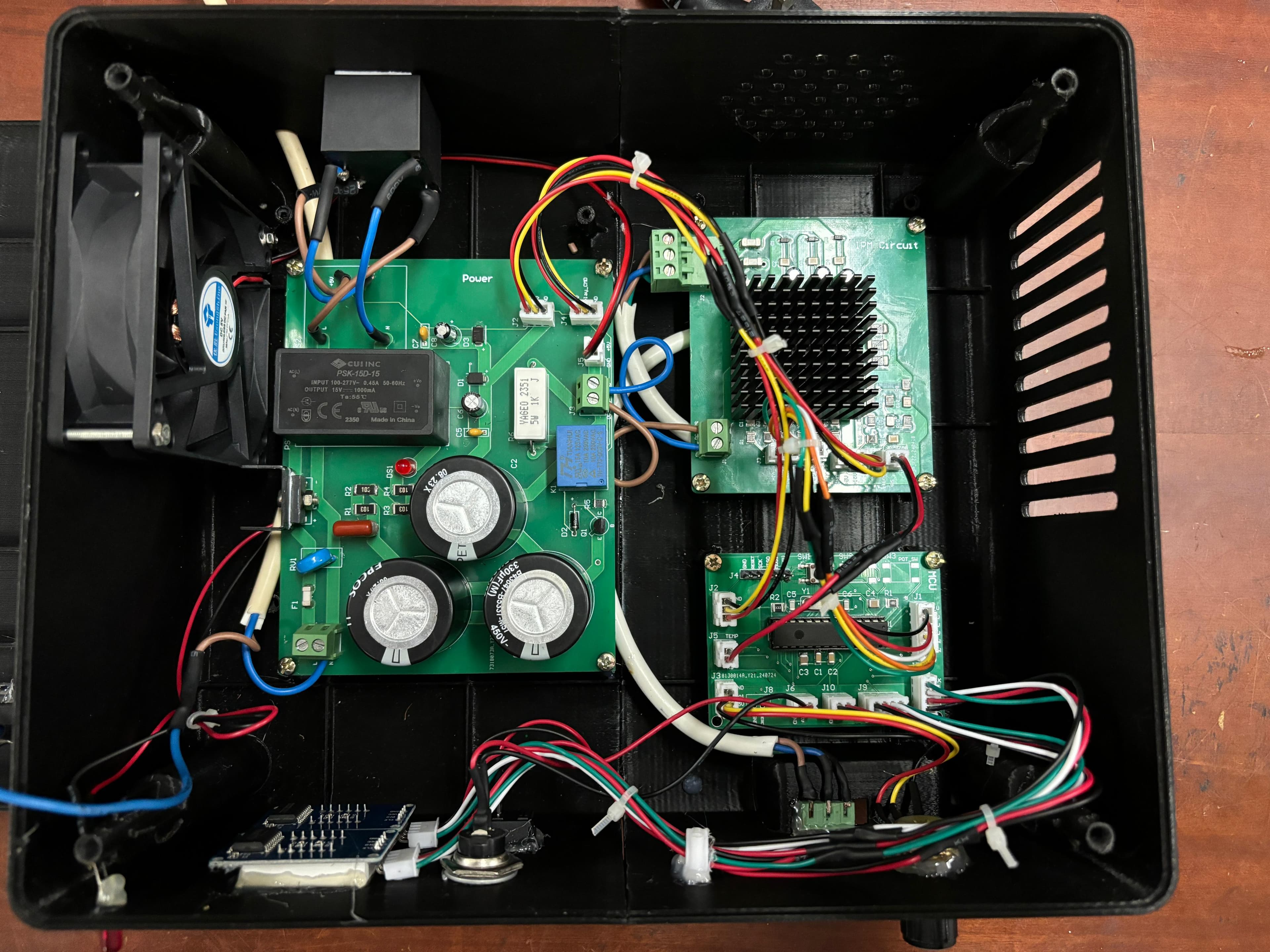

Designed and prototyped a Variable Frequency Drive (VFD) for AC motor speed control. I focused on firmware development (Arduino → AVR C/C++), enclosure and mold-ready casing design, component selection support, documentation, and hands-on testing including PCB soldering and system validation.

Project Overview

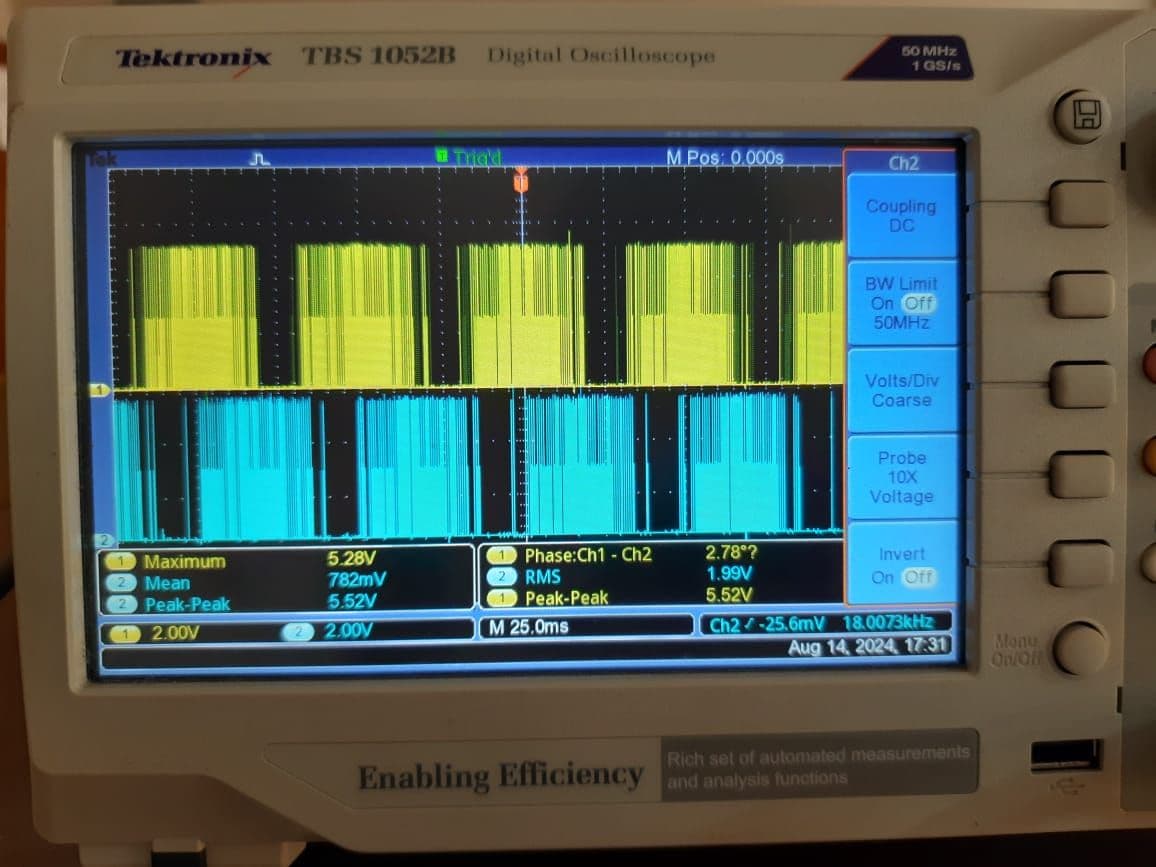

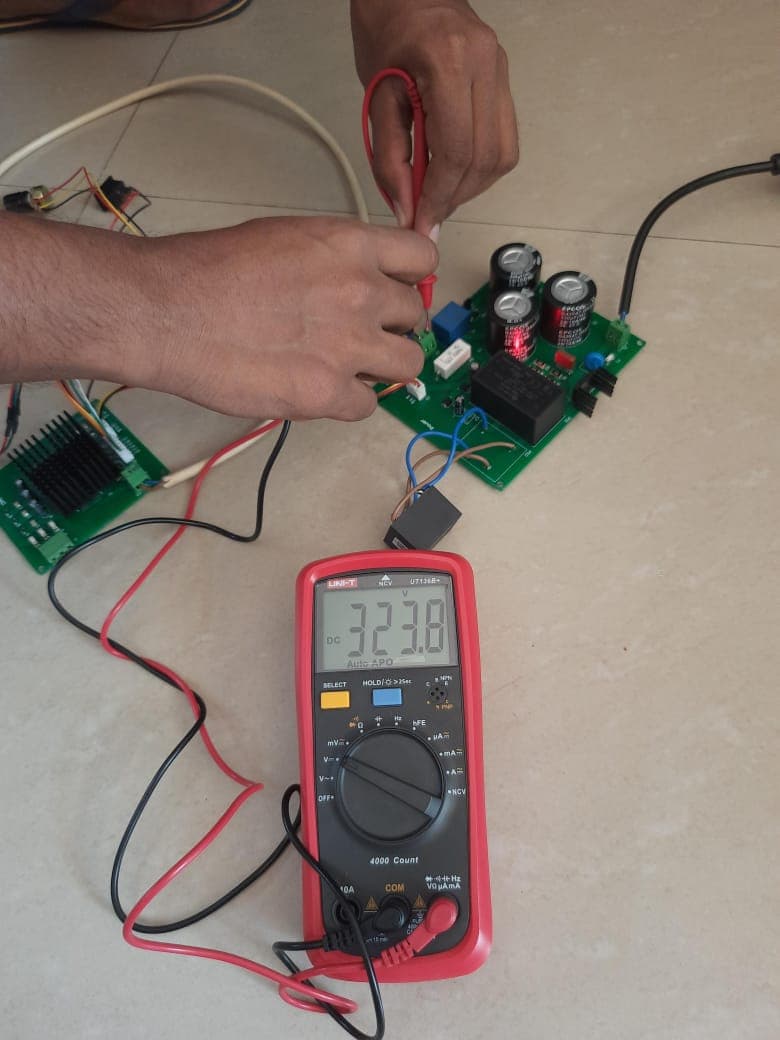

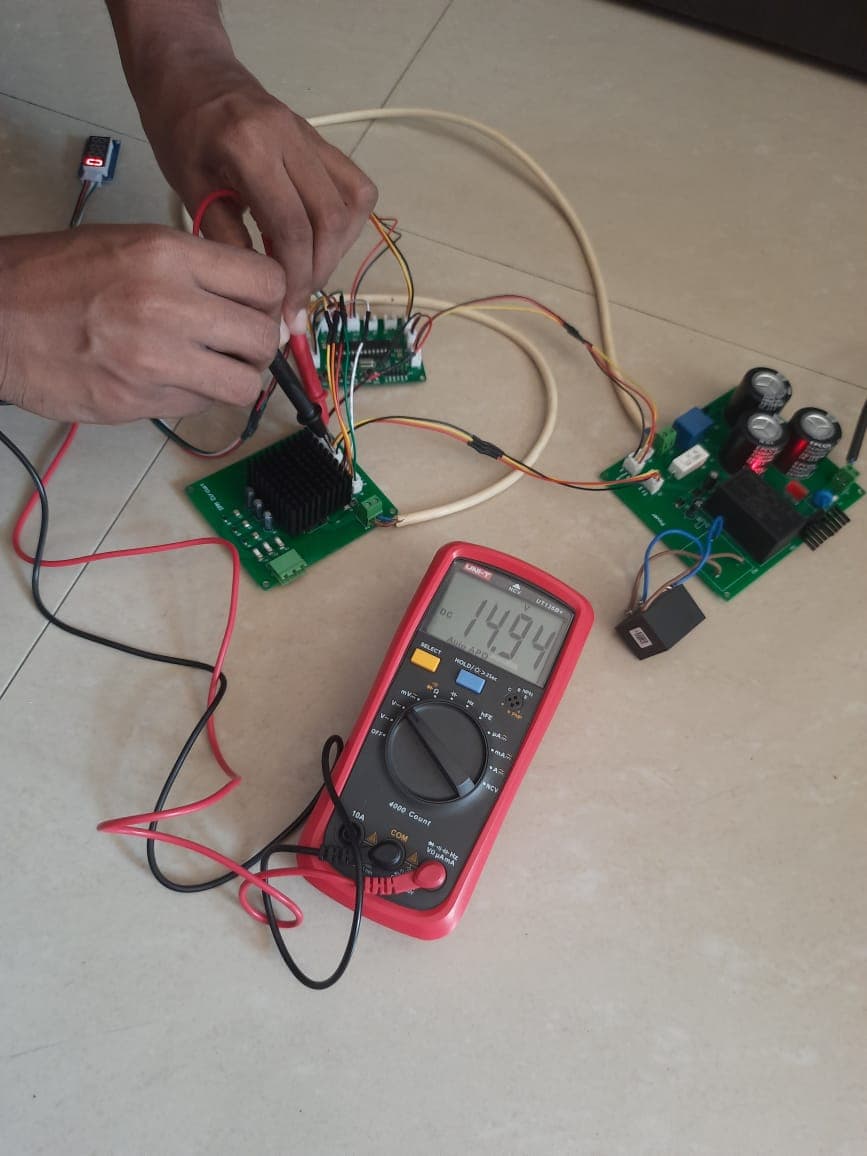

This project involved designing and building a Variable Frequency Drive (VFD) to control the speed and torque of an AC motor by varying the output frequency and voltage. The system integrates a high-voltage power stage, an inverter module, and an embedded controller to generate PWM signals and manage user inputs. The final prototype was tested on an AC motor to verify stable operation and speed variation.

Control Method (V/f Control):

We implemented V/f control, a common approach for induction motor drives. The inverter output frequency sets the motor speed, and the output voltage is scaled with frequency to keep the motor flux stable. This provides reliable speed control with a relatively simple control structure.

Team and My Role

This was a two-person project. My main responsibilities were:

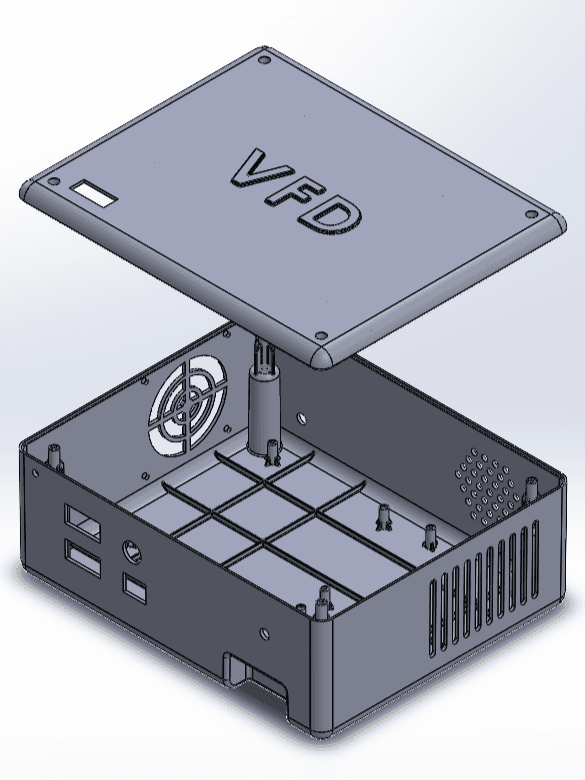

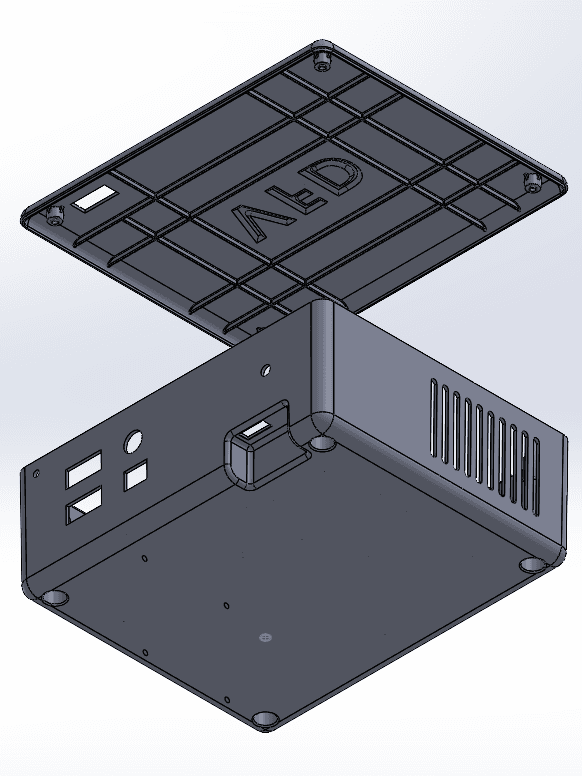

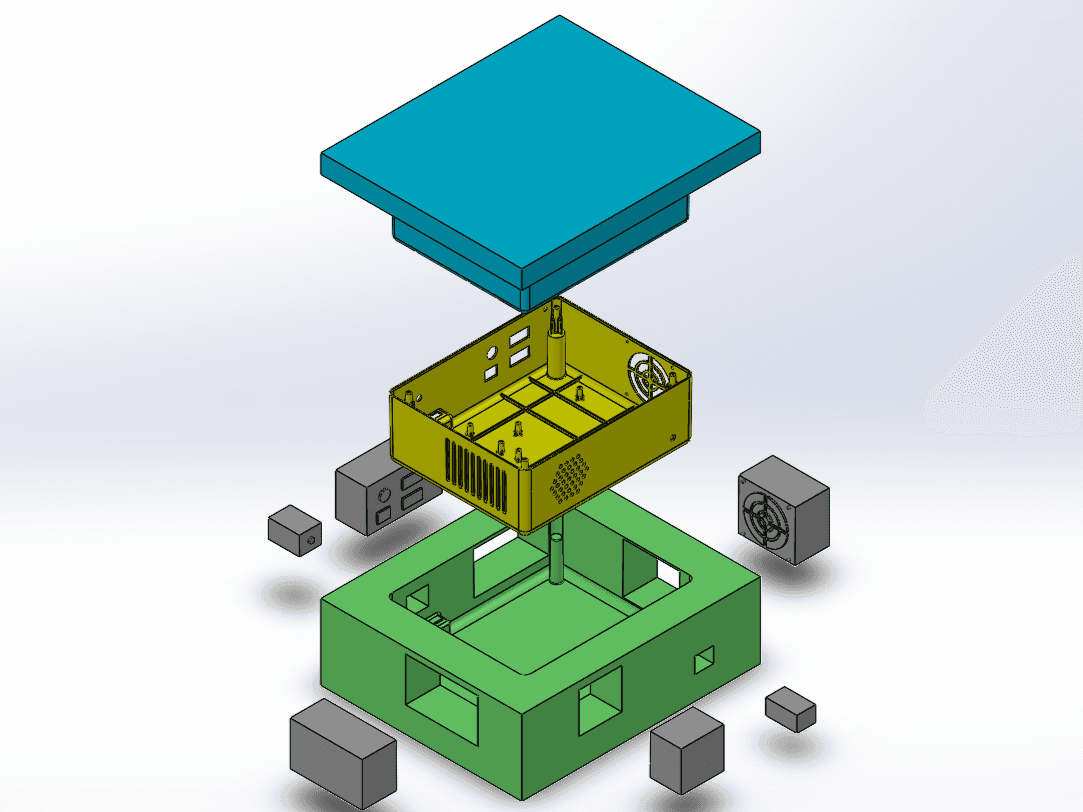

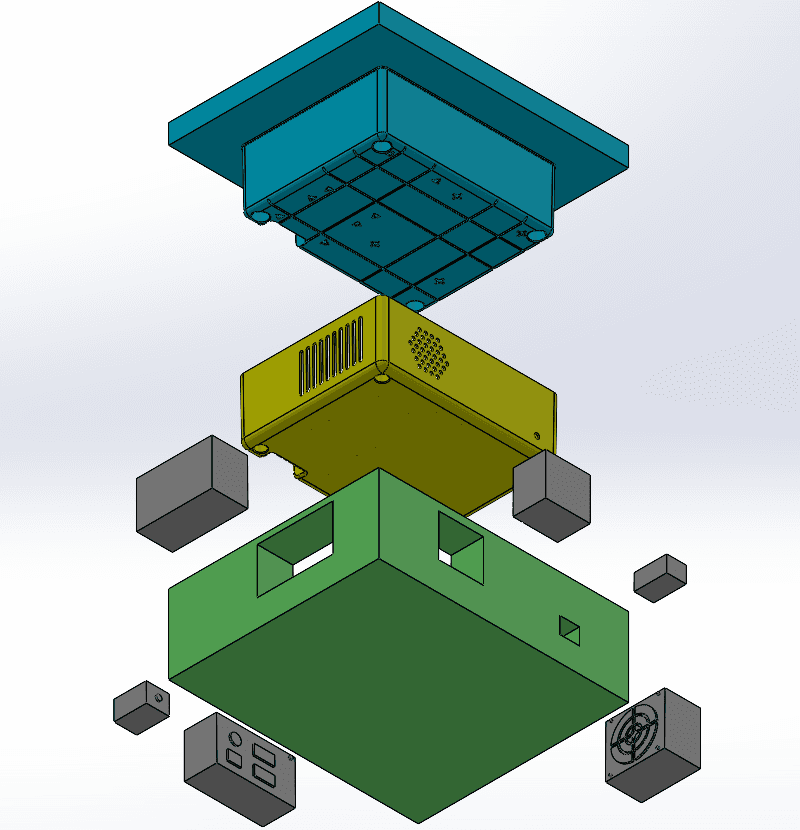

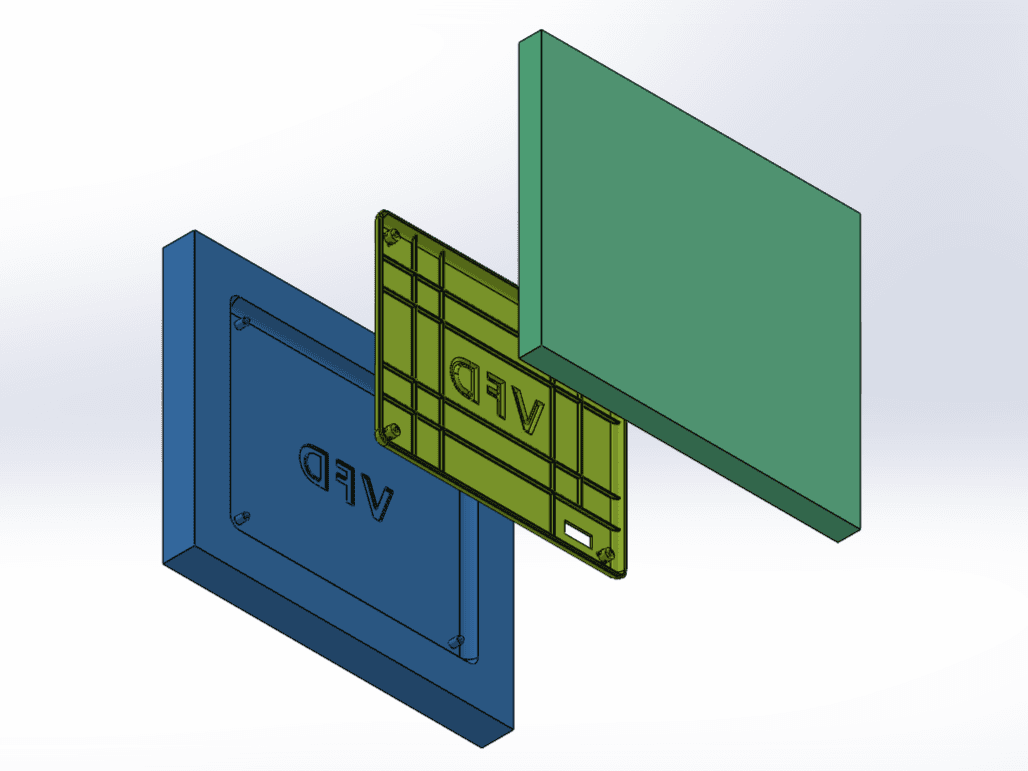

- Enclosure and mold-ready casing design: Designed the protective enclosure with a focus on a moldable structure and practical assembly.

- Firmware development: Adapted an existing Arduino-based control approach into a more direct AVR (ATmega328-PU) C/C++ implementation, improving control over timing and hardware-level behavior.

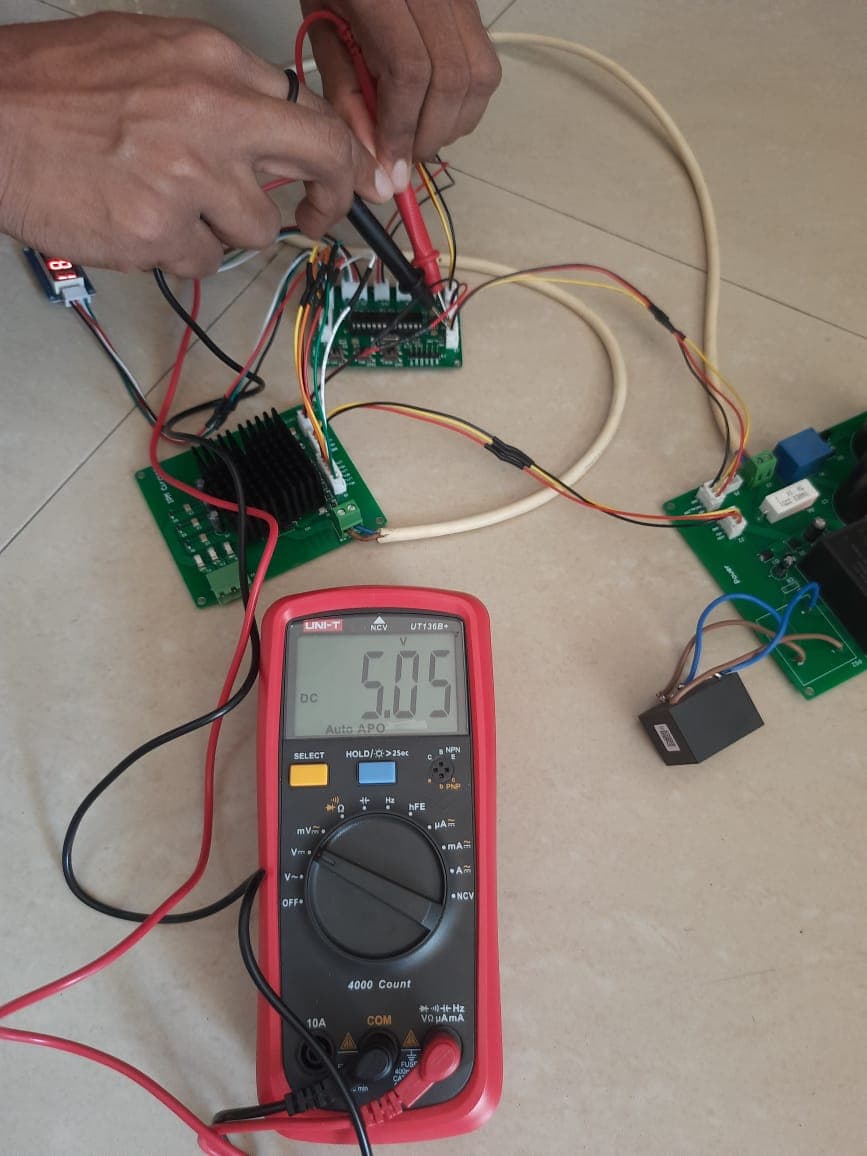

- Testing and validation: Supported system testing and debugging, including PCB soldering, measurements, and validating PWM generation and power rails.

In addition, I contributed to documentation, assisted with circuit design where needed, and supported component selection based on electrical and practical constraints.

What I Delivered

- A working embedded firmware workflow for motor control (PWM generation and basic user control handling).

- A completed enclosure design suitable for prototyping and aligned with manufacturing-oriented thinking (moldable structure).

- Practical integration and testing contributions that helped verify stable behavior of the final prototype.

Skills Demonstrated

- Embedded firmware development (Arduino to AVR-level implementation)

- Practical prototyping and debugging (soldering, measurement-driven testing)

- Mechanical/product thinking for electronics (enclosure design for protection and manufacturability)

- Technical documentation and design support

Gallery